The optical glass is where the magic really happens in binoculars, scopes, and lenses. The quality of the glass (and how it’s coated and polished) makes a huge difference in sharpness, brightness, color fidelity, and low-light performance.

Best Optical Glass Makers (Lenses & Prisms)Japan — The King of Optical Glass

Ohara is especially respected for their ED and high-transmission glass used in astronomy and high-end camera optics. Germany — Legendary Quality

Schott invented many of the specialty glasses used in APO and HD lenses. Their prisms and coatings are top-tier. Russia — Underrated Glass

China — Improving Rapidly

Key Terms to Look For in Optical Glass:

|

How to make glass for binoculars?

Normal glass as everyone knows it, essentially consists of sand (silicon dioxide), soda ash, and limestone. But this can not really be used for optical instruments. A special glass with special properties is required for optical applications.

In order to manipulate the properties of glass for optical applications, ‘impurities’ such as boron, barium, fluoride, sodium, potassium, calcium, aluminum, lead and their oxides and compounds are added to the molten glass.

Depending on the quantity and mixture of those ingredients, the resulting optical glass has different properties regarding transmission, refraction, reflection, and absorption.

The glass used in optical instruments

The glass produced for optical lenses and prisms is primarily Crown Glass and Flint Glass. These can have different qualities and optical properties depending on the mix of glass melt ingredients. The designers of binoculars and telescopes combine different glasses with different optical properties to cancel out unwanted aberrations of lenses until bright, cris,p high-quality images in true color are produced.

Type of glass used in making lenses and prisms

Crown glass is a glass with a high content of potassium oxide (“potash”). It is a hard optical glass with an Abbe number of around 50 to 60. Due to this low refractive index and low dispersion, crown glass is used to produce achromatic lenses.

Flint glass is a very clear and highly transmissible glass, commonly used for lenses and prisms. It is manufactured from potassium and lead-silicates, resulting in a glass with a much higher dispersion and higher index of refraction than crown glass (thus a lower Abbe number). Particularly important are its properties to reduce certain aberrations in combination with crown glass. (Achromat).

BK7 and BaK4 Glass

The prisms in the binoculars are usually made of BK7 or Bak4 glass. Both are types of crown glass, which differ in their optical properties and price.

BK7 glass is a very common Borosilicate crown glass. It is widely used for lenses and prisms in the budget and medium price range.

Bak4 – Barium crown glass has better optical properties, but is more expensive to manufacture and therefore usually found in high-quality optics and premium binoculars. The higher transmission of BaK4 glass provides better detail resolution and a brighter color-true image.

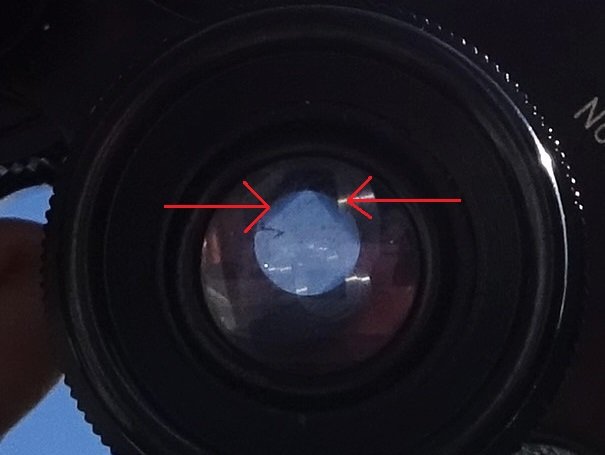

A simple test can reveal whether BK7 or BaK4 glass is used in the binoculars. Hold the binoculars about an arm’s length away against a bright background and look at the exit pupil. If the exit pupil appears with square, slightly darkened fields at the edge, it is Bk7 glass. If it looks nice round and without dark shades, then it is a BaK 4 glass.

What is ED-Glas?

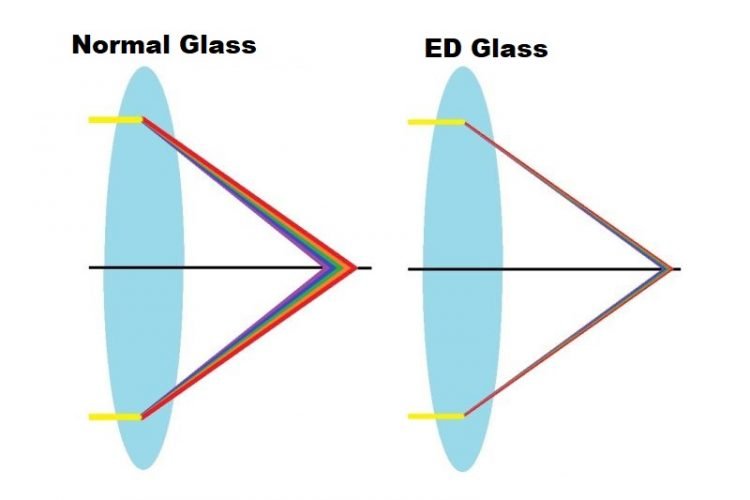

ED glass (Extra-Low-Dispersion Glass), is a special glass that contains calcium-fluoride; it is also known as Fluoride glass. ED glass is complex in its production and processing and is therefore usually found only in premium binoculars.

Fluoride glass has a very low refractive index, which means that the bending and breaking of light into its primary colors (dispersion) is less than with a glass with a higher refractive index.

Lenses made of Extra-Low-Dispersion Glass reduce chromatic aberration (color fringing), resulting in an exceptionally detailed, true-to-color, extremely contour-sharp, and high-contrast image.

But ED glass alone cannot work magic and does not make “super binoculars”. ED glass can only lead to better results if all other parameters are already optimally coordinated.

Regular HD glass lenses in the hands of the best binocular makers might produce better results than ED glass handled by an inexperienced binocular maker.

Standard glass lens = More color fringing |

Low dispersion glass = Less color fringing |

|

|

|

Image Errors – Aberration in binoculars

Creating perfect binoculars is impossible. Light behaves according to the laws of physics. This causes more or less severe errors in image projection. However, the optics designer can apply those laws to minimize image errors in binoculars (aberration) as much as possible, by skillfully combining the properties of the optical components.

Dispersion

The term dispersion comes from the Latin word “dispersio” and means “to spread”. In optics, it describes the separation of white light into its constituent colors according to wavelength. Just think of how a rainbow is formed.

The term dispersion comes from the Latin word “dispersio” and means “to spread”. In optics, it describes the separation of white light into its constituent colors according to wavelength. Just think of how a rainbow is formed.

When light travels through different media, the speed of light changes. The change in speed depends on the medium’s refractive index as well as on the wavelength of the light.

For example, when light is passing through a prism or a lens, long-wave red light is refracted less than the short-wave violet light.

Sending white light through a prism demonstrates how light is fanned out into a spectrum, it is divided into its color components. Dispersion of light is also responsible for the red of a sunset or sunrise

A perfect lens would focus all wavelengths into a single focal point. Unfortunately, there is no perfect lens.

Chromatic Aberration – Color Fringing

Dispersion of light is responsible for chromatic aberration, the appearance of color fringes on high-contrast images (as shown exaggerated in the eagle images further above).

Especially in cheap binoculars, color fringing may occur. Chromatic aberration appears when viewing an object against a high-contrast background. A viewer will then notice bluish edges around the viewed object.

Manufacturers of binoculars try to reduce this phenomenon by designing complex optical systems in which errors of different glass cancel each other out. This can be done through lens systems combining two or more lenses, such as the Achromatic doublet seen below.

What is an Achromatic Doublet

Extra-low dispersion glass is used in the objective lens systems of premium binoculars and good birdwatching binoculars to compensate for the different degrees of refraction of the color components (wavelengths) of a light beam.

Extra-low dispersion glass is used in the objective lens systems of premium binoculars and good birdwatching binoculars to compensate for the different degrees of refraction of the color components (wavelengths) of a light beam.

An Achromatic doublet is such a lens system. Properties of different glass types reduce the blurred edges and color distortions and the image is much more detailed and color-true.

What is Spherical Aberration?

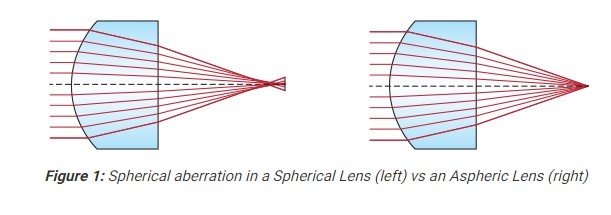

In cheap binoculars, a decreasing image sharpness towards the edge of the projected images can appear. Depending on the quality of the binoculars, this blur may be strong to barely perceptible.

The reason for this phenomenon known as Spherical Aberration is that the incoming light that passes through a spherical lens ends up focusing at different points after passing through that spherical lens. In other words, light rays that are near the horizontal axis and rays further from the axis are not focused on the same point of the optical axis.

Spherical aberration can cause blurring in the picture and affect resolution and clarity, making it hard to obtain sharp images. The below images show Spherical Aberration:

Spherical Aberration, reduced sharpness at the image periphery |

No Spherical Aberration, Clear High Resolution at the image periphery |

|

|

|

This error caused by a spherically curved lens surface can be corrected with the help of aspherical lenses or through lens systems that combine convex and concave lenses to move the foci in different directions.

What is lens coating for?

Coating the lenses and prisms is essential to improve the image quality of binoculars. Coating the glass refers to thin metal oxide layers that are vapor-deposited on optical glass. The purpose of lens coatings is to minimize reflection on the glass surface, thus increasing the light transmission of the optical system. Depending on the metal oxide used, the layer thickness and refractive index of the oxide reflections and aberrations are reduced. In premium binoculars, as many as seven or eight coatings may be applied to cover the entire wavelength of the visible spectrum to achieve the best possible light transmission. Lens coatings greatly determine the quality and the price of binoculars.

Sources:

edmundoptics.com/resources/application-notes/optics/optical-glass/

sciencedirect.com/topics/engineering/spherical-aberration

photographylife.com/what-is-chromatic-aberration