The optical elements, which are essential for the functioning of binoculars, are accommodated in the housing. Most occasional users don’t think twice about the binoculars’ housing as long as the instrument is working. However, a precisely manufactured housing, which protects the optical components and ensures the correct and stable position of all assemblies relative to one another, is required, so that the binoculars withstand tough handling and adverse weather conditions and temperature fluctuations.

A prerequisite for all of these requirements is a solid and durable raw material that has been precisely shaped into a precision mechanism. Dust and water must be kept out to ensure the mechanics and the internal optical parts keep on working.

What Are Binoculars Housings Made Of

Binoculars are used outdoors in nature, be it hiking, hunting, or birdwatching, you have to carry them. Therefore, they should be lightweight but made of a durable material that protects the instrument from the elements and guarantees perfect functioning. Housings and tubes of binoculars are made out of aluminum alloys, magnesium alloys or polycarbonate plastics which are usually coated with a non-slip rubber coating that offers grip and protection against bumps.

Aluminum

Aluminum alloy: The properties of aluminum; light, robust, durable, inherently corrosion-resistant, inexpensive, and easy to work with, make it a very suitable material for binoculars.

Magnesium

A high-quality material that is a third lighter than aluminum and has excellent properties. It is robust, durable, and corrosion-resistant. It is not as common as Al and requires somewhat more complex processing. Due to the slightly higher price, it is more likely to be found in premium models from high-end optics manufacturers, although there are exceptions.

It is not used in its pure form but as a Magnesium alloy. Magnesium alloys are mixtures of magnesium with other metals which are then referred to as alloys. Depending on the application, different high proportions of aluminum, zinc, manganese, silicon, copper and zirconium are used. Magnesium is the lightest structural metal. A common alloy is Magnalium, an aluminum alloy with 5% magnesium and 95% aluminum.

Polycarbonate

is a polymer plastic that can be found in all kinds of everyday objects in any shape, application, and material properties. It is an inexpensive and easy to manufacture material that is easy to work with, corrosion-proof, stable, and very strong. High strength polycarbonate bodies are typically used in many budget to mid-range binoculars

Rubber Armour

The metal or polycarbonate housings of most modern binoculars are fitted with a rubber armor that protects the binoculars from light impacts and mechanical influences. Rubber armoring also contributes to improved grip and handling of binoculars.

How to clean sticky rubber on binoculars

The rubber on binoculars degrades over the years; it becomes brittle and cracks or another problem is sticky rubber on binoculars.

Whether it is natural rubber or synthetic rubber, both types will degrade. This is due to the necessary additives and plasticizers that disintegrate over time, evaporate or react with other substances (sweat, bug repellents, etc., ).

To stop this problem, you can clean the rubber surfaces with rubbing alcohol and carefully dust it with pure talcum powder.

However, this is only a temporary fix, the degradation of the rubber cannot be stopped. Check with the manufacturer if these parts can be replaced.

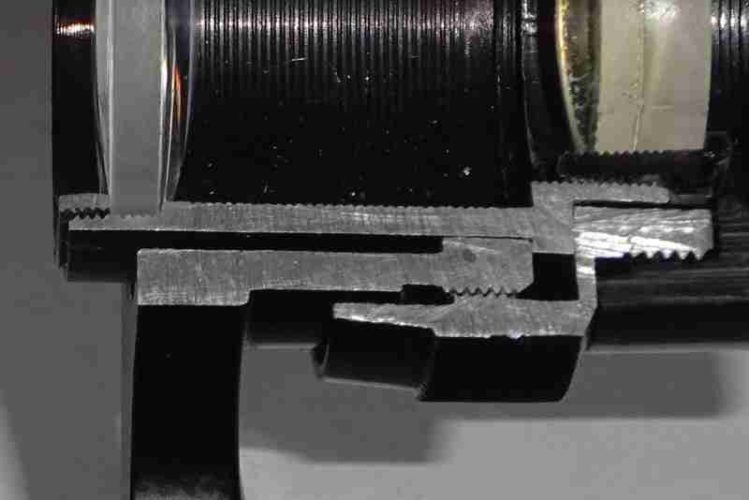

Waterproofing and O-ring sealing

Sealing the binoculars housing against water increases the usability of the instrument greatly. Unfortunately, as the instrument’s waterproof rating increases, so will the price. To properly seal the entire assembly of a pair of binoculars, several seals and O-rings are required that are durable enough to withstand daily use in sometimes harsh environments for many years.

Weather Resistant vs Waterproof vs Fog Proof

No rating: Binoculars without weather protection are the cheapest option, but are also limited in their use. They may withstand a few raindrops or a spray of water, but since moisture may get in just too easy, they are unsuitable for demanding outdoor use. They are more of a choice of the occasional user.

Water-resistant or weather-resistant: It is difficult to classify this rating, and to know what is really meant by it. Various manufacturers probably stretch this rating. The respective product descriptions may explain whether seals are installed or the lenses are glued in, and so on. In general, this rating lets you use these binoculars in some rain and damp conditions without causing damage.

Waterproof and O-ring sealed: This is what you want! Waterproof and O-ring sealed means that all parts and assemblies of the binoculars sealed, and that water and moisture cannot get in. Some binoculars withstand pressure and are submersible to certain depths. This is especially desirable for Marine binoculars.

The waterproof rating often goes hand in hand with the term fog-proof. This refers to O-ring sealed instruments where in the last manufacturing step, dry air (zero humidity), or nowadays often an inert gas such as nitrogen or argon is filled in, to prevent fogging.

Argon vs nitrogen purge

Regardless of whether the binoculars housing is flushed with argon or nitrogen, both should remove water vapor, which is part of the normal ambient air, from inside the binoculars and thus avoid internal condensation in the event of abrupt changes in temperature.

Purging the air and replacing the reactive oxygen contained therein with an inert gas also has the advantage that the internal corrosion is reduced and the service life of the required lubrication of the moving parts is extended.

However, the law of diffusion requires that the proportions of the gases in a gas mixture equalize over time until “equilibrium” is reached. In practice, this means that the gas, whether nitrogen or argon, escapes over a period of time and be replaced by normal ambient air. Refilling is an option.

Argon molecules are larger than nitrogen molecules, so theoretically it takes longer for the larger argon molecules to escape and air and water molecules to enter the instrument. It is difficult to verify whether this is always the case in the real world. In my view, it doesn’t matter if argon or nitrogen is used, as long as the binocular seals are in order.

Buy the binoculars with the most waterproof rating you can afford

Since binoculars are used outdoors in nature, it can only be an advantage if they are 100 percent waterproof and fog proof. Only then are they guaranteed to function reliably even under the toughest conditions.

The quality of binoculars housing, its careful manufacture using the best materials, should not be neglected and is an important factor when looking to buy binoculars.